Before jumping directly to heat sinks, let us first have a review on power and how to calculate it.

Power

Electric power, or simply power, is the rate (per unit time) at which an electric circuit transfers electrical energy. Watt is the SI unit of power, and that is equivalent to one joule per second. There is also a term called “wattage,” used colloquially to mean “electric power in watts.” The letter P represents electric power.

Electric batteries and generators supply electric power. But electric power industries supply electric power to homes as domestic mains electricity and businesses through an electric power grid. Electric power is used for many applications such as motion and light or heat with high efficiency. It can be delivered over long distances by transmission lines.

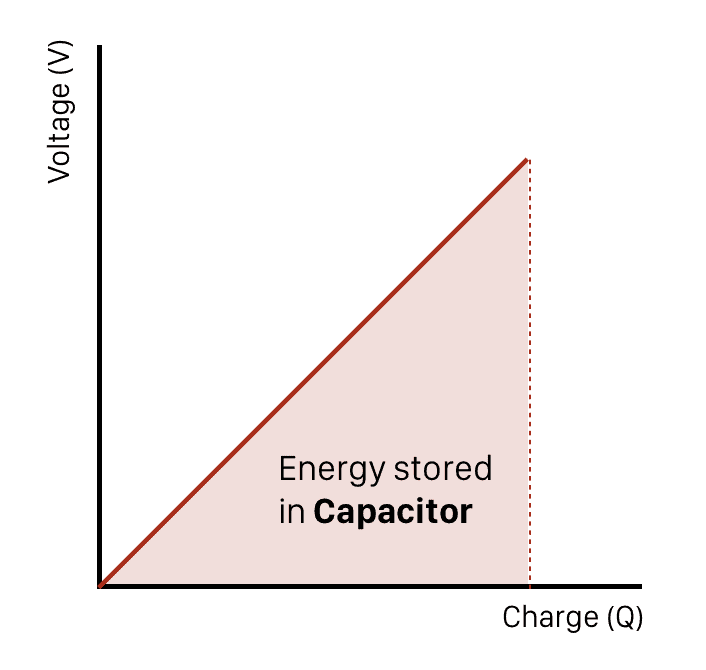

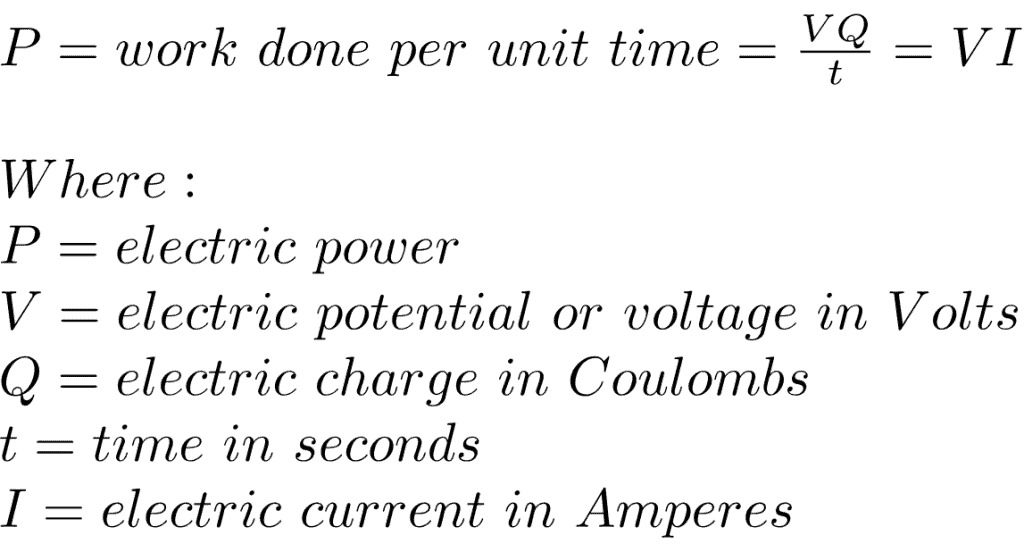

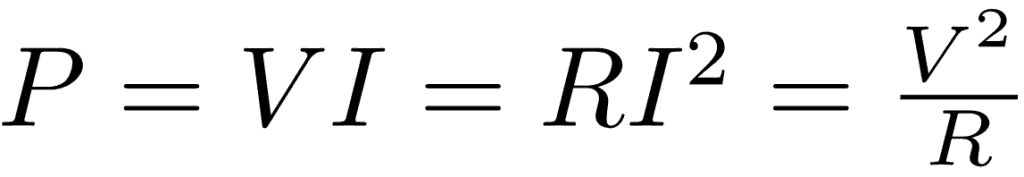

The electric power in watts produced by an electric current I consisting of a charge of Q coulombs every t seconds passing through an electric potential difference of V can be calculated with this equation:

Now, in resistive loads or resistive circuits, there is another formula to solve for electric power. To obtain electric power, we use an alternative expression for the amount of power dissipated. Ohm’s law (V=IR) is combined with the formula for electric power (P=VI):

How to Calculate Power Loss Due to Heat

If a current I flows through a given element in your circuit, losing voltage V in the process, then the power dissipated by that circuit element is the product of that current and voltage: P = I × V.

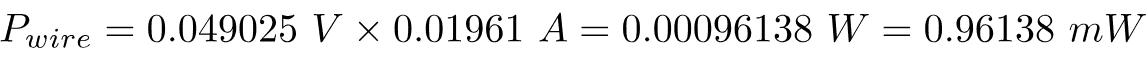

Take this for an example: You have a 5V power supply with one 250Ω and two wires of 2.5Ω each. The voltage drop over one piece of wire is 0.049025V. Now, the current through your circuit is 0.01961A. To calculate the power loss in one wire, we use the formula for power:

Types of Thermal Heat Conduction

In general, conduction is the transmission of energy from one particle to the other. Heat conduction is the flow of energy from a higher temperature to a lower temperature. When this occurs, there is no change in the molecules’ position; they simply vibrate amongst each other. Remember that heat energy is usually transferred from a molecule to another molecule as they are in direct contact.

Conduction of Heat

This occurs when molecules increase in temperature. These molecules vibrate, and this vibration or movement passes the heat energy to the surrounding molecules. Some examples for this type are touching a hot pot (accidentally) and placing a heating pad directly to your skin to warm your muscles.

Conduction of Electricity

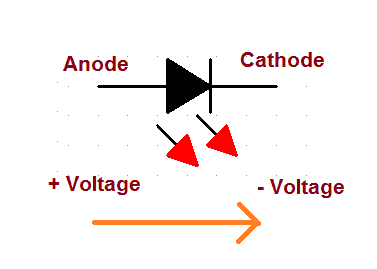

This occurs due to the movement of electrically charged particles through a medium. This movement results in an electric current that is carried by electrons or ions. One example of this is when you accidentally get electrocuted when you touch a live wire. This is because your body contains water, which is a conductor of electricity. Another example is when electricity passes through wires, which are conductors.

Photoconductivity

This occurs when a material absorbs electromagnetic radiation, resulting in a change in the substance’s electrical conductivity. Electromagnetic radiation can be caused by something as simple as a light shining on a semiconductor. When this event occurs, the number of free electrons increases, as does the number of electron holes. Thus, increasing the object’s electrical conductivity. Applications for this include solar panels, copy machines, and equipment for infrared detection.

Types of Thermal Heat-Resistant Materials

Heat-resistant materials provide safety advantages, especially to individuals working in heated or hot environments (steel mills and forgeries). A lot of companies are looking for heat-resistant materials for production. Also, homeowners need these materials for protection and prevention. Heat-resistant materials are now protecting workforces and changing the way many companies do business.

- Fire Sleeves

This is one of the leading applications of heat-resistant materials. It protects firefighters from the high temperatures they battle on a daily basis. Fire sleeves are used on firefighting equipment to protect cables and other important equipment from being damaged by extremely high temperatures.

- Fire Barrier Sealants

Especially useful for industrial companies working in high-temperature manufacturing, these caulk-like sealants can be used to fire-proof rooms and other structures. Fire sealing is an important process in manufacturing. Fire barrier sealants are designed to the highest levels of heat resistance to ensure both the safety of their application and the workers’ safety.

- Fire Resistant Wire

Fire resistant wire is manufactured using heat-resistant insulating materials. These wires are used by electricians to limit damage if a fire impacts the interior of a building. Since the wires are flame resistant, fire can’t travel along the cable to other parts of the building.

- Steel

Steel is a very safe and durable material which makes it a top choice for builders. It is non-combustible and fire-resistant. Unlike other materials for building, this material takes much longer to get affected by the fire. So, this is ideal if you want a safe home hardly impacted by fires.

- Heat-resistant Tapes

These tapes can be very helpful for protecting tubing and wiring in very hot environments like a car or boat engine bay. Heat resistant tape outperforms other types of tapes for high heat applications. These tapes can withstand high temperatures, making them a good choice for mechanics repairing engines or other hot equipment. These come in different sizes, and widths depending on the type of job you need to complete.

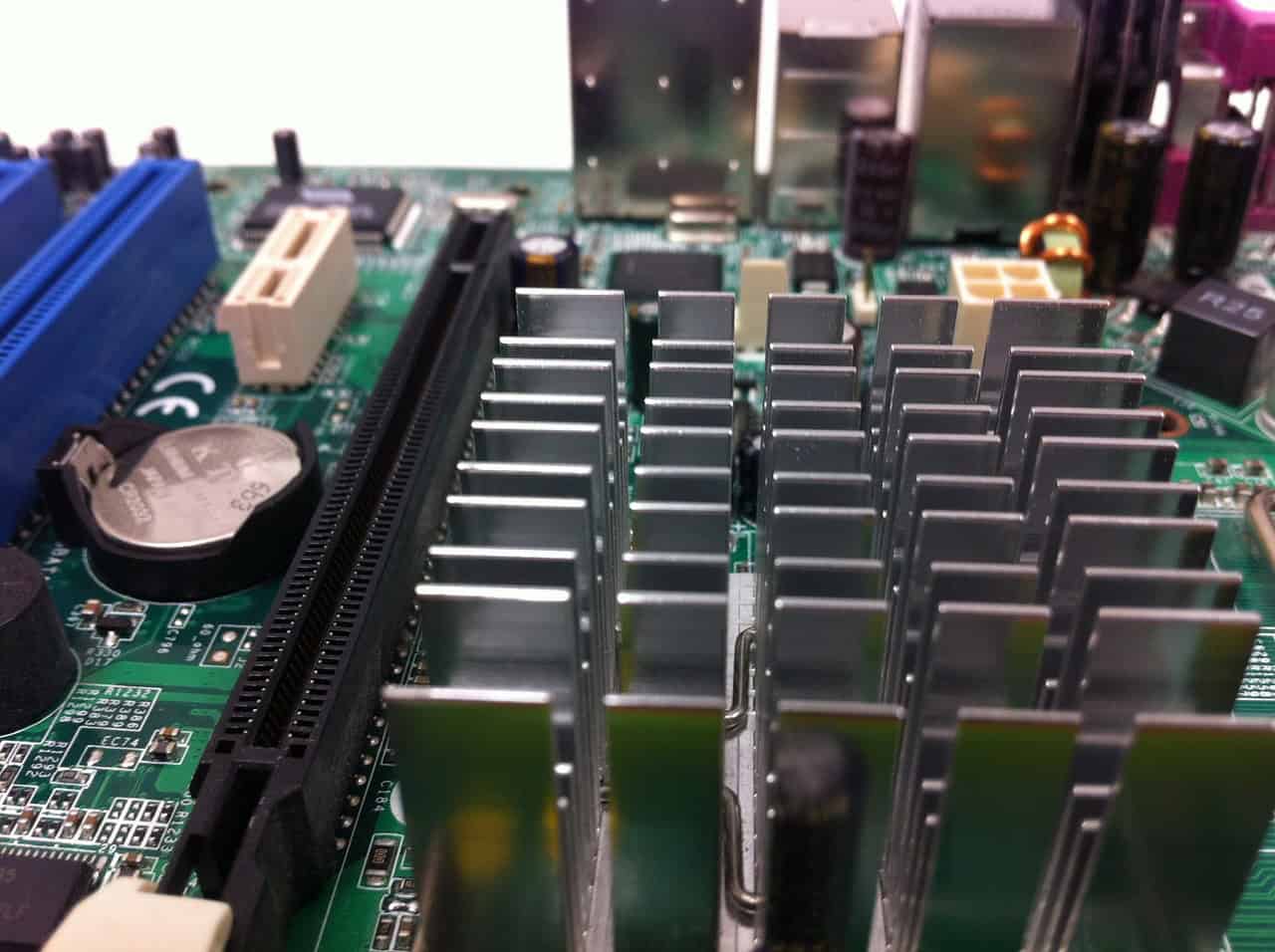

Uses for Heat Sinks

A heat sink is basically a device that incorporates either a fan or some other means to keep a hot component from overheating and to help it cool down. It is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. The heat sink allows the regulation of the device’s temperature. Heat sinks are mostly used in computers to cool CPUs, GPUs, and some chipsets and RAM modules. They are designed to maximize their surface area in contact with the cooling medium surrounding them, such as the air. Heat sinks are also used with high-power semiconductor devices such as power transistors and optoelectronics devices such as lasers and large light-emitting diodes (LEDs).

But why are heat sinks used in these high-power semiconductor devices? It is because the heat dissipation ability of these semiconductor devices is insufficient to moderate its temperature.

Types of Heat Sinks

- Active

This type of heat sink utilizes the computer’s power supply. This may also include a fan. Active heat sinks are usually referred to as heat sink and fan (HSF). If you are looking for these, recommended are those with ball bearing motors rather than sleeve bearings. Popular in recent years, you can also use liquid cooling systems.

- Passive

This type of heat sink has no mechanical component. However, passive heat sinks are very reliable. They usually are made of aluminum-finned radiator that dissipates heat through convection. There should be a steady airflow moving across the heat sink’s fins for it to work at full capacity.

Calculating Heat Sink Size

Calculating heat sink size can be a daunting task, especially for someone without much thermal analysis experience. But there are many heat sink design software online that can help with heat sink size calculation. Such software allows you to design and analyze a heat sink to meet the device’s thermal requirements. In manual calculation, dimensions are needed to determine an appropriate design for your heat sink. The following steps will help reduce the complexity of the calculations. To get a rough estimate of the size of the required heat sink, consider the following:

- The surface is due to the fins’ thickness, and the base’s thickness should be smaller than the total surface area of the heat sink.

- The thermal conductivity of the heat sink is high enough. This is so that the temperature of the surface of the heat sink is uniform and approximately equal to the heat source’s temperature.

- The heat source has the same length and width as the heat sink.

- The heat source is centered on the base of the heat sink.

How to Install a Heat Sink

In installing a heat sink in a CPU, you need to do it on the motherboard. Taking the motherboard out of the case allows checking for extra room for components during installation. You can choose to put a fan along with the heat sink because a fan moves the heat away from the heat sink. That way, it becomes a two-part cooling device. But check first if it will fit. The assembly usually has a three-pin power connector. You need to prepare the cable and the motherboard connector for the heat sink assembly. Then, follow these steps:

- Align the CPU so that Connection 1 indicator is lined up with Pin 1 on the CPU socket. Ensure the orientation notches on the CPU and are aligned with the orientation keys on the CPU socket.

- Place the CPU gently into the socket.

- Close the CPU load plate. Close the load lever to secure it in place and move it under the load lever retention tab.

- Apply a small amount of thermal paste to the CPU. Make sure to follow the current application instructions provided by the manufacturer of your thermal paste.

- Align the heat sink and fan assembly retainers with the holes on the motherboard.

- Place the assembly onto the CPU socket. Be very careful not to pinch the CPU fan wires.

- Tighten the assembly retainers to secure the assembly in place.

- Connect the assembly power cable to the CPU fan connector on the motherboard.

Using Fans to Help Heat Sinks Cool

Almost all computers have heat sinks. These help keep the CPUs cool, which then prevents them from overheating. However, sometimes heat sinks can become too hot. This can happen if the CPU is running at full capacity for an extended period of time. It can also happen if the air surrounding the computer is too hot.

Combining a fan and a heat sink is often used to keep both the CPU and the heat sink at an acceptable temperature to avoid issues or problems about overheating. The fan pushes hot air away from the computer and moves cool air across the heat sink. A thermometer is also present in a CPU to keep track of the processor’s temperature. If the temperature becomes too hot, the fan then functions and may speed up so the processor and the heat sink will cool down much faster.

Hope this article has helped you understand electrical heat and how to use heat sinks! Please leave a comment below if you have questions about anything.